Gulf weather doesn’t give Panama City businesses much of a break. Between high winds, driving rain, and relentless sun, your roof is either prepared, or it’s vulnerable. As Ready Nation Contractors (RNC US), we operate as a true Panama City commercial roofing company, built for Gulf Coast conditions and the Florida Building Code.

In this guide, we share what makes commercial roofing in Panama City unique, which systems perform best, and how our process, from assessment to closeout, keeps operations running with minimal disruption. We’ll also touch on budgeting, warranties, insurance coordination, and how to choose the right partner. Along the way, you’ll find helpful resources and direct links to key Ready Nation Contractors services so you can take the next step with confidence.

Why Panama City’s Climate Demands Specialized Commercial Roofing

Wind Uplift, Hurricanes, And Florida Building Code Compliance

Gulf Coast wind events can turn exposed edges and weak seams into failure points in minutes. Florida Building Code wind maps assign higher design pressures to our region, so edge metal, fastener density, and attachment patterns must be engineered, not guessed. Our crews design and install for wind uplift resistance and document compliance. When severe weather is approaching or has passed, we mobilize quickly for temporary dry‑in and repairs through our dedicated storm damage emergency response.

Heat, UV, And Salt-Air Corrosion Resistance

Panama City’s heat index, UV exposure, and salt‑laden air accelerate aging across membranes and metals. We specify UV-stable single-ply membranes, marine‑grade coatings, and corrosion‑resistant fasteners and flashings. Reflective, “cool” roof assemblies can also reduce heat load on HVAC equipment, an operational win that pairs well with our HVAC services.

Drainage, Ponding, And Low-Slope Design

Most commercial roofs here are low‑slope. If drains clog or slopes are inadequate, ponding water stresses seams and increases leak risk. We correct slope where feasible, add or rework drains and scuppers, and set a maintenance cadence so debris doesn’t sabotage performance. If you’re seeing stains or active leaks, start with fast triage via our roof repair team.

Best Roofing Systems For Gulf Coast Commercial Buildings

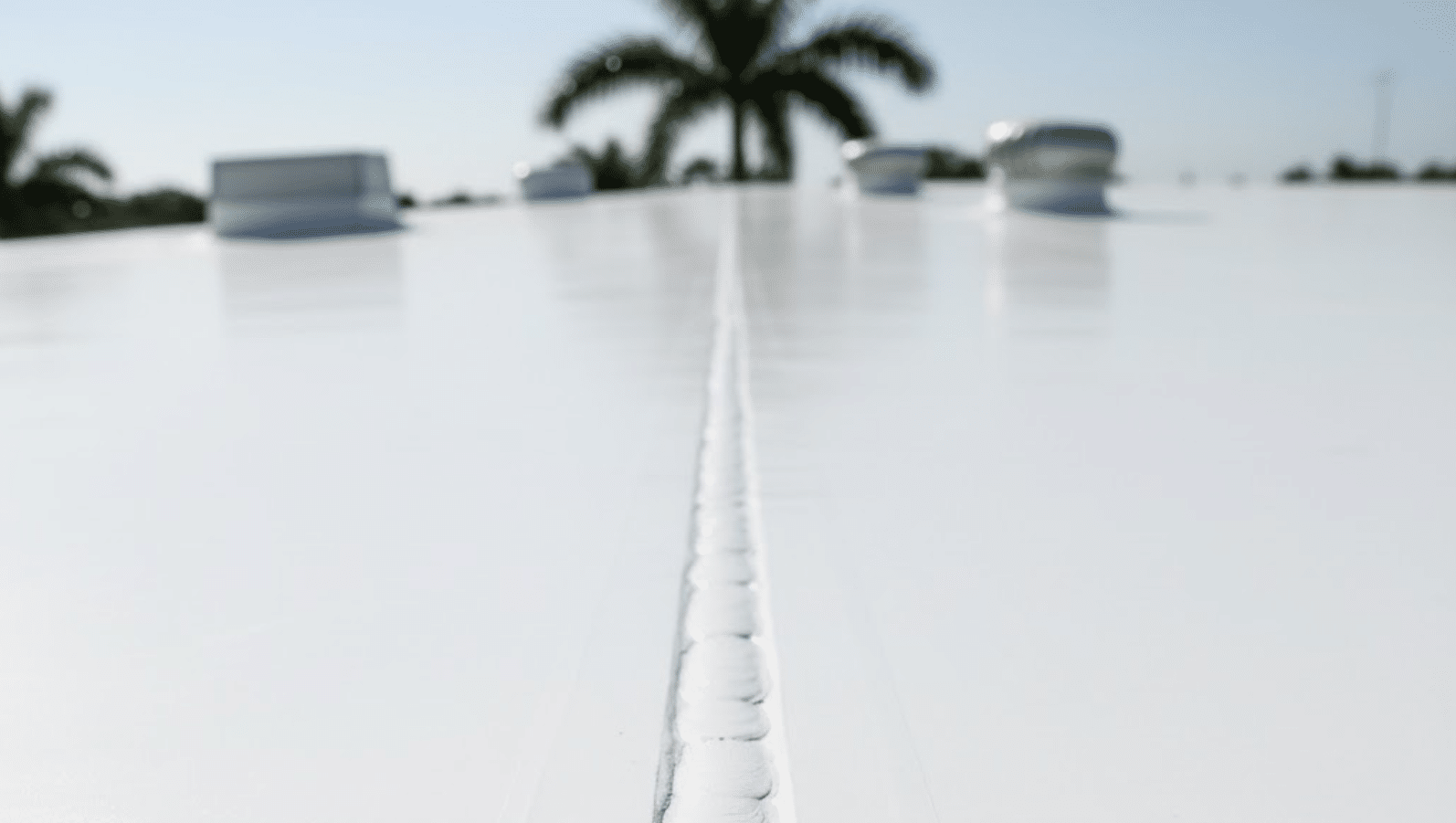

TPO And PVC Single-Ply Membranes

Heat‑welded seams, reflective surfaces, and robust chemical resistance make TPO and PVC strong contenders on Florida low‑slope roofs. Proper substrate prep, uplift‑tested attachments, and reinforced perimeter details are critical to meet FBC wind requirements and extend service life.

Modified Bitumen And Built-Up Roofing

Multi‑ply systems (mod‑bit and BUR) deliver layered redundancy and excellent puncture resistance. With high‑quality cap sheets and UV‑stable surfacing, they stand up well to foot traffic and seasonal extremes, especially on facilities with frequent rooftop activity.

Standing Seam Metal And Retrofit Systems

For long-span or steep‑slope conditions, standing seam metal offers longevity, exceptional wind resistance, and easy integration of high‑reflectance finishes. Retrofit systems can overlay aging assemblies (when structurally appropriate) to reduce tear‑off disruption while upgrading wind performance.

Roof Coatings And Spray Foam For Restoration

Coatings and SPF can restore weathered roofs, improve insulation values, and create seamless waterproofing, often at a lower cost than full replacement. Success depends on meticulous surface prep, adhesion testing, and moisture surveying. We evaluate restoration viability as part of our commercial restoration program to help you stretch capital without sacrificing reliability.

Services Across The Roof Life Cycle

New Construction, Tear-Offs, And Re-Roofs

From design‑assist on new builds to complete tear‑offs, we coordinate structure, roof assembly, and code compliance to deliver durable, warrantable systems. When a re‑roof makes more sense than endless patchwork, we’ll outline options and phasing through our general contracting team.

Leak Repair, Emergency Tarping, And Storm Response

Leaks don’t wait for business hours. We deploy rapid diagnostics, temporary dry‑in, and permanent repairs with documented photos and pressure‑test results. Start a ticket with roof repair or call our 24/7 line: for larger events, see our storm damage services.

Preventive Maintenance And Roof Asset Management

Planned maintenance reduces surprise outages. Our asset management includes semiannual inspections, debris removal, drain clearing, minor repairs, and condition reporting with projections for budgeting. We share practical tips on our blog.

Service Areas: Panama City, Panama City Beach, Lynn Haven, Callaway, And Bay County

Our Panama City hub covers Bay County, plus we support the broader Gulf and statewide network. If you operate across Florida or beyond (Tampa, Miami, St. Petersburg, Odessa, Austin, Dallas, Lafayette), view our current locations to coordinate multi‑site programs.

Our Process: From Assessment To Closeout

On-Site Evaluation And Scope Development

We start with a hands‑on inspection. Depending on your roof, we may perform infrared scans, moisture probes, core cuts, and fastener pull tests. You’ll receive a clear condition report and options aligned with code, warranty eligibility, and operational constraints.

Proposal, Scheduling, Permitting, And Safety Plan

Every proposal details scope, materials, attachments, and schedule. We handle permitting and craft a site‑specific safety plan that accounts for tenants, logistics, and noise. Transparency is the goal, no surprises, just steady progress. Learn more about our team on the About RNC US page.

Installation, Quality Control, And Closeout Documentation

During install, our supervisors verify substrate readiness, attachments, and flashing details. We capture progress photos, perform water‑test or scan checks as appropriate, and assemble a closeout package with warranties, product data, and maintenance guidance. For specialized occupancies, see our industries served.

Budgeting, Warranties, And Insurance Considerations

Lifecycle Costing And Value Engineering

The cheapest roof rarely costs least over 20+ years. We model lifecycle costs, installation, maintenance, energy, and projected repairs, so you can compare TPO/PVC, mod‑bit/BUR, metal, or restoration options with real numbers. We’ll also flag energy savings that can lighten HVAC loads: explore related upgrades with our HVAC team.

Warranty Options And Owner Maintenance Requirements

Manufacturer and contractor warranties vary by term and coverage. Most require documented maintenance and prompt leak reporting. We outline what’s covered, what’s not, and set a service plan to keep your warranty in good standing. Routine care is easy to schedule through our roof repair desk.

Insurance Claims: Documentation, Adjusters, And Timelines

When weather pushes water where it doesn’t belong, documentation matters. We create photo logs, moisture maps, and itemized estimates that align with adjuster expectations. If interior drying is needed, our water damage restoration team can work in parallel to minimize downtime. For general disaster guidance, see FEMA and the State of Florida’s resource hub at FloridaDisaster.org. Best‑practice research is also available through the Insurance Institute for Business & Home Safety.

How To Choose A Panama City, FL Commercial Roofing Contractor

Licensing, Insurance, And Safety Record

Insist on proof of Florida licensing, current insurance, and a written safety program. A transparent safety culture shows up in pre‑task plans, lift training, and housekeeping. You can also review standing with the Better Business Bureau.

Manufacturer Specifications And Quality Assurance

Ask how crews are trained on the specific system you’re buying (TPO, PVC, mod‑bit, metal, coatings) and whether the installer holds current manufacturer approvals. Request sample QA checklists and an example closeout package so you know what deliverables to expect.

Local References, Project Fit, And Communication

Good project fit beats the lowest bid. Look for local references with similar square footage, occupancy, and complexity. Clear communication, who your PM is, how often you’ll get updates, what happens if weather delays, keeps business disruption to a minimum. Explore our background and case stories on the About page and recent posts on the RNC US blog.

Conclusion

As a Panama City commercial roofing company, we build for the realities of the Gulf: wind, water, heat, and salt. From code‑compliant design and resilient systems to disciplined maintenance and responsive recovery, Ready Nation Contractors keeps your operation covered, literally and strategically. If you need rapid leak repair, a re‑roof budget, or a multi‑facility plan, we’re ready.

Call RNC US 24/7 at 877‑762‑2858, or request service via our Contact page. Planning a project across multiple sites? Coordinate with our locations. For storm readiness and restoration beyond roofing, explore storm damage services and our broader commercial restoration capabilities.

Panama City Commercial Roofing FAQs

What does a Panama City commercial roofing company do to handle wind, heat, and salt air?

In our Gulf climate, a Panama City commercial roofing company engineers edge metal and fastener patterns to Florida Building Code wind maps, specifies UV-stable single-ply or marine-grade finishes, and uses corrosion‑resistant fasteners and flashings. They also improve drainage and set maintenance to prevent ponding, leaks, and premature membrane or metal failure.

Which roofing systems are best for Gulf Coast commercial buildings?

TPO and PVC excel with heat‑welded seams and reflectivity; mod‑bit/BUR offer multi‑ply durability; standing seam metal delivers top wind resistance; and coatings or SPF restore aging roofs cost‑effectively. Success hinges on proper substrate prep, uplift‑tested attachments, and reinforced perimeters to meet Florida Building Code pressures and extend service life.

How does a Panama City commercial roofing company manage projects from assessment to closeout?

A Panama City commercial roofing company begins with on‑site evaluation (infrared scans, core cuts, fastener pull tests) and a clear scope. Next come scheduling, permitting, and a site‑specific safety plan. During install, QA verifies attachments and flashings with photo documentation. Closeout provides warranties, product data, and maintenance guidance to minimize disruption.

Do you provide emergency leak repair and storm response in Bay County?

Yes. Teams deploy 24/7 for rapid diagnostics, temporary dry‑in or tarping, and permanent repairs, with photos and pressure-test results. Service covers Panama City, Panama City Beach, Lynn Haven, Callaway, and Bay County, with coordination for larger events through storm damage services and insurance-friendly documentation to speed claims.

How long do TPO, PVC, metal, or coated roofs last near the coast?

Typical lifespans with maintenance: TPO/PVC 15–25 years; mod‑bit/BUR 20–30; standing seam metal 30–50+; coatings 10–20 depending on thickness and recoats; SPF 20–30 with topcoat renewals. Coastal salt air and UV accelerate aging, so semiannual inspections, drain clearing, and prompt repairs are essential.